Hangar at Concord Airport will be Region’s First Building with Engineered Timber

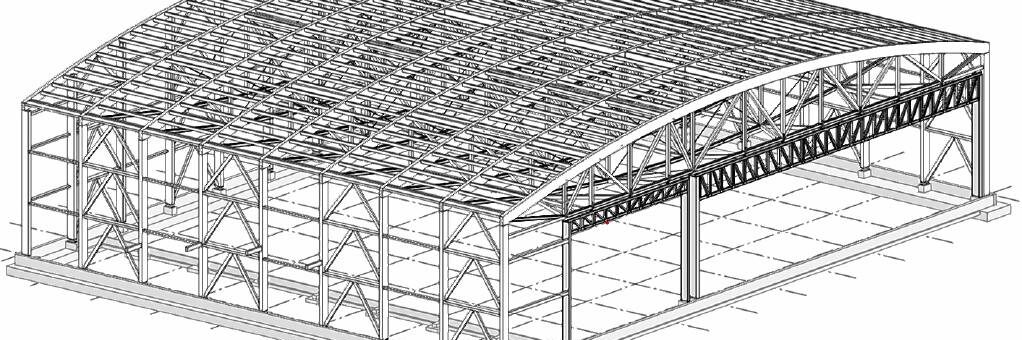

NH – Business boosters are excited about the expansion of biotech firm United Therapeutics in New Hampshire. Still, the corporate hangar it will build at Concord Municipal Airport is exciting for another reason: Glulam. Lots and lots of glulam. “The entire skeleton and truss system is glulam. We’ve never done anything like it, and I don’t think many have,” said Evan Herron, project manager for Silver Maple Construction of New Haven, Vermont.

Glulam is a term for wood beams and panels made by gluing together smaller layers of wood, or laminations, into pieces that are big enough and strong enough to replace steel and even concrete in commercial buildings. It is part of the industry trend of engineered lumber, which has a number of names, including mass timber, that combines smaller pieces of wood in novel ways to make large construction products. Engineered lumber is still fairly uncommon, but its use is growing, and around the world, it has replaced structural steel and concrete in buildings as tall as 25 stories. At least one commercial building has been built in New Hampshire with engineered lumber: an office block in Portsmouth made with cross-laminated timber or CLT.

The 210-by-170-foot airplane hangar planned at Concord airport by United Therapeutics, a Maryland medical research company, will be the first in the Concord area. The advantages of engineered lumber are partly aesthetic: It can be shaped in interesting ways and made to look great since, after all, it is wood. But the big benefit is the environment. Using wood in commercial buildings can lock away tons of carbon contained in the trees and, perhaps more importantly, avoids the carbon pollution that would have been generated by making steel or concrete, both of which produce large amounts of greenhouse gases.

Increasing the use of engineered lumber in commercial and industrial construction is one of the many changes we have to make to limit future damage from climate emergencies. That is a big reason United Therapeutics is using glulam in Concord, Evans said. “They don’t care just about building nice buildings, but environmentally sustainable buildings,” he said. Art Massif, the Quebec firm making the glulam beams, estimates it will trap 522 tons of CO2, which it claims is equivalent to removing 104 cars from the road for a year. Engineered lumber has another advantage for heavily forested New Hampshire. It provides a new market forger for those portions of trees that can’t be turned directly into boards.